Izixhobo zomphezulu womatshini wokungqusha, sinoomatshini abachanekileyo abahlukileyo bokuwugubungela.Umatshini wokungqusha ophathwayo we-gantry, umatshini ophathwayo wokusila, umatshini wokungqusha we-keyway, iimodeli eziguquguqukayo ziyafumaneka kumsebenzi wokugaya.Nokuba ngoomatshini abathathu bokungqusha, okanye izixhobo ezi-2 zomatshini wokusila ophathwayo.

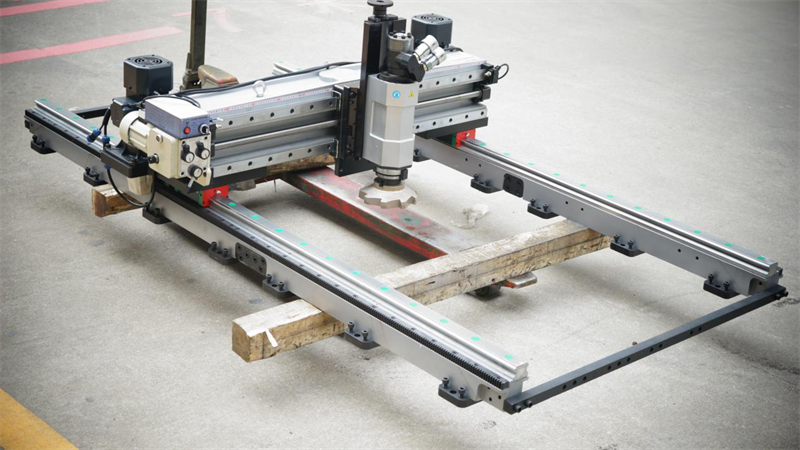

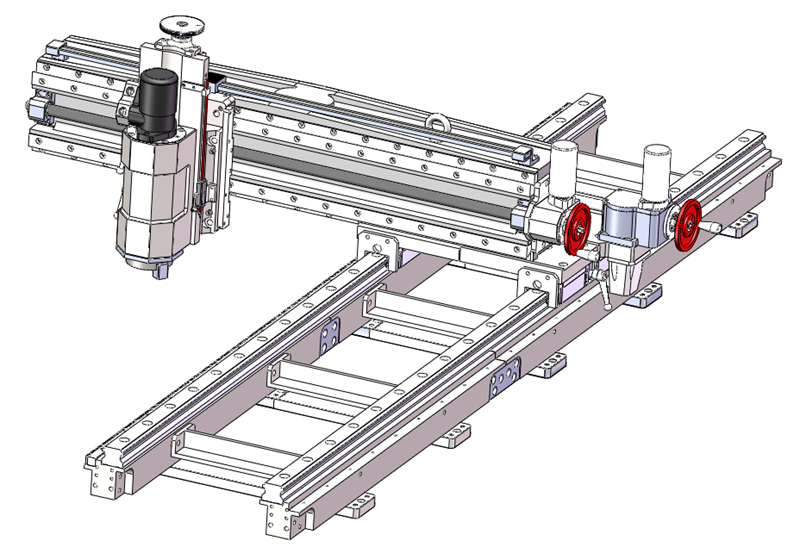

GMM2000 umatshini wokugaya ophathwayo we-gantry unokulungiswa phantse kuyo nayiphi na indawo.Umzimba ophambili we-Y axis eyenziwe ngeAluminiyam, kukukhanya okuphathekayo okugqithisileyo ngaphandle kokuphulukana nobungqongqo.I-X axis eyenziwe ngentsimbi yesakhiwo, yomelele ngokwaneleyo kwaye izinzile kwisiseko.Ibhedi eqinileyo iyafumaneka ukuba yandiswe imilo eyahlukeneyo ngokwebala.

Oomatshini bokungqusha obuphathekayo bayilwe ngenkqubo kaloliwe yokwahlulahlula ukwenza lula zombini i-linear kunye ne-gantry milling kunye nobuncinci bokutshintsha.

Senze ngokwezifiso oomatshini abafanayo abaphathwayo bokungqusha.Yeyomsebenzi wesiza, kwaye iyaphatheka kunye nemithwalo yokupakisha.

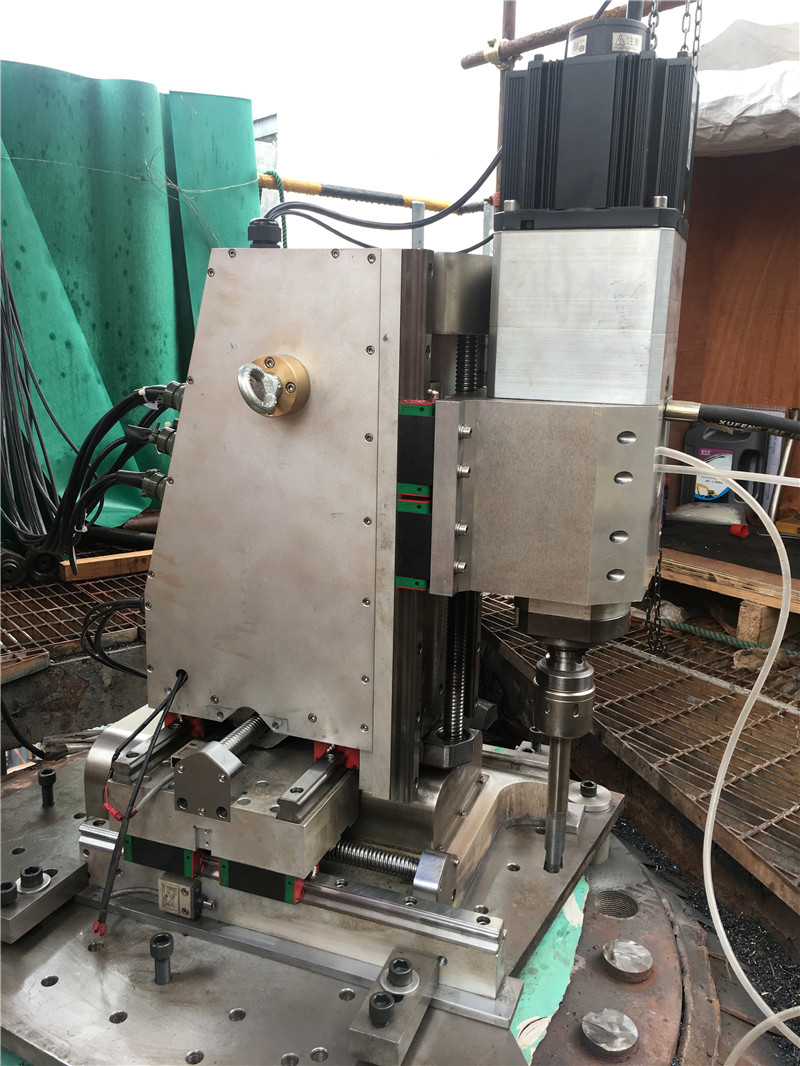

I-Weld bead shavers enemodeli yombane yeepleyiti iyafumaneka.

Kwi-weld bead shaver, inokulungiswa kwi-plate okanye ngamatyathanga kumbhobho.Umsebenzi ophathwayo we-gantry wokugaya umphezulu wenza ukuba oomatshini bokucheba i-weld bahlangane, balula ngaphandle kokulahleka kokuqina.

Isetyenziselwa ukusetyenzwa kwendiza yombhobho, i-welding seam milling.Weld ukucheba amaso ukwenzela iipleyiti.Ingasetyenziswa ekusetyenzisweni kobubanzi bombhobho ohlukeneyo okanye ukucaciswa komthungo ohlukeneyo we-welding.Ifanelekile kwaye iyakhawuleza, inokwenziwa ngokwezifiso njengesicelo.

Umzi-mveliso wethu uya kwenza umazibuthe ulungise isiseko njengoko kufuneka kumatshini ophathwayo wokusila.

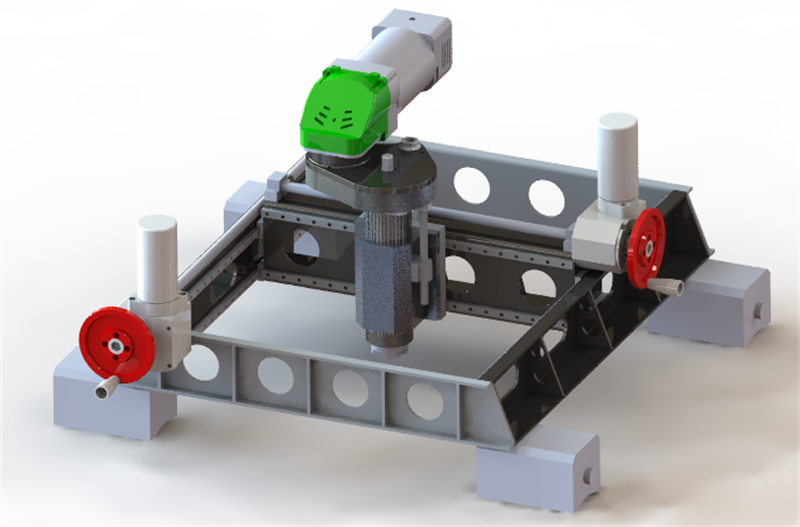

I-axis enye, i-axis e-2, i-3 axis ephathwayo koomatshini bokungqusha bayafumaneka kwisixhobo somatshini wesiza esihambisa unyamezelo kwiworkshop.Kwisiza esiphathwayo somatshini wokungqusha wesixhobo sokusila sinokuxhonywa kwizixhobo zokusebenza ngeendlela ezininzi ezahlukeneyo kunye neendawo ezininzi, kubandakanywa iibholithi, iziqhoboshi zamakhonkco, iipleyiti zombingelelo, utshintshe iimagnethi okanye njengoko kufunwa ngokweendawo zokusebenza zesiza.

Oomatshini bokungqusha abaphathwayo benza ukuba ukuguba okuchanekileyo, ukugrumba, kunye nokukruqula kwenziwe ngokufanelekileyo ukuhlangabezana nokunyamezelana okuqinileyo.

Ukulungiswa kwendawo yeflange, sinokwenza umatshini wokusila we-cnc ukuba wenze ukususwa kwe-stud, ukusika intambo.

Umatshini wokugaya umsonto we-CNC

Isicelo somatshini wokugaya i-Oli, iGesi kunye neMichiza, iSixhobo soMbane esiManzi soMbane, ukwakhiwa kweenqanawa kunye nokulungiswa.

Usetyenziso oluqhelekileyo:

• Iiflange zesixokelelwano semibhobho

• Iiflange zevalvu kunye neeflange zebhonethi

• Iiflange zokutshintsha ubushushu

• Iiflange zenqanawa

• Ubuso obunamaphiko kwiinkqubo zemibhobho

• Iiflange zezindlu zempompo

• Ukulungiselela ukuwelda

• Iityhubhu zeshiti iinyanda.

• Iziseko zokuxhoma

• Iindawo zokugqibela zokuqhuba

• Ubuso bezixhobo zenkunzi

• Ukwenziwa kwezixhobo zemigodi

• Iringi zokusila

• Iziseko zokuxhoma

• I-Crane pedestal flange.